Al Shboul Metal mining services department created to be a solution provider for the industry

with all means of productivity and reliability products we offer. We thought will be industry partner

in progress.

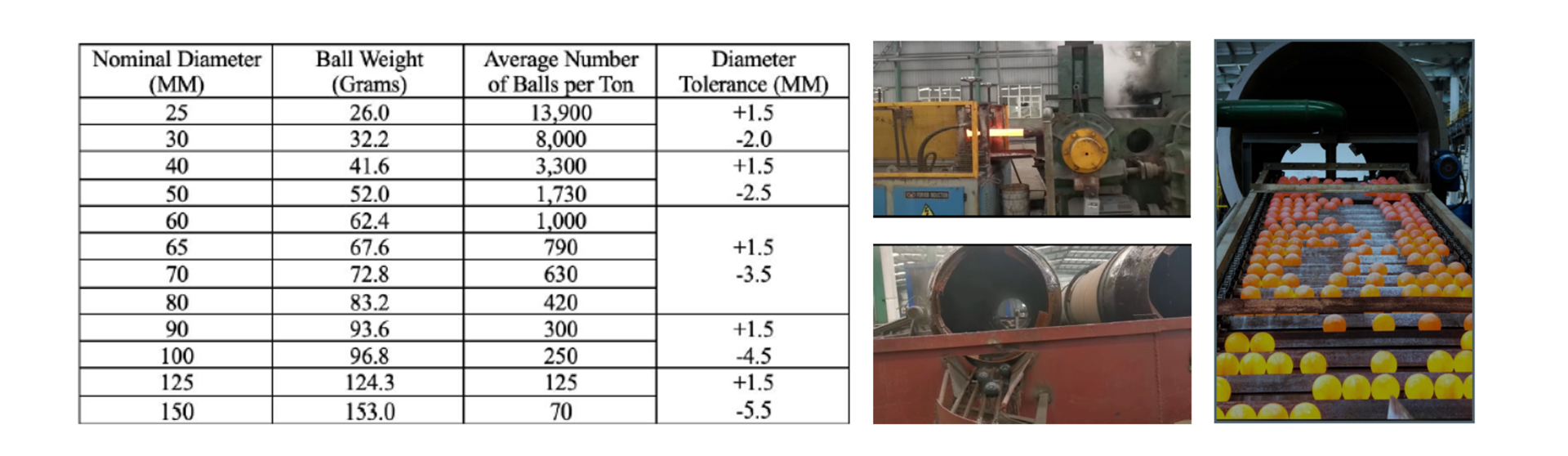

- Grinding Media Balls

Full range of grinding media balls and rods with forged or casted manufactured.

Hardness range for forged and casted balls are 60-65 and 60-68 respectively. In some critical

applications and cases the hardness may vary depends on raw material type and mill conditions

Broken Rate less than 1%

Wear Rate varies from 100 – 700 g/ton depends on size, raw material and mill conditions

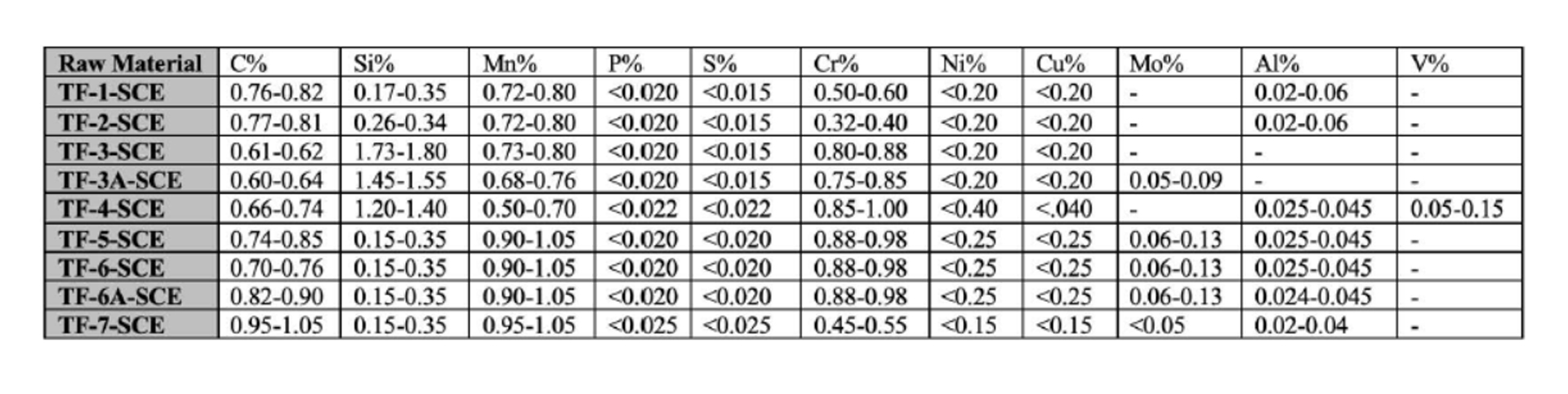

- Forged Balls Chemical Composition

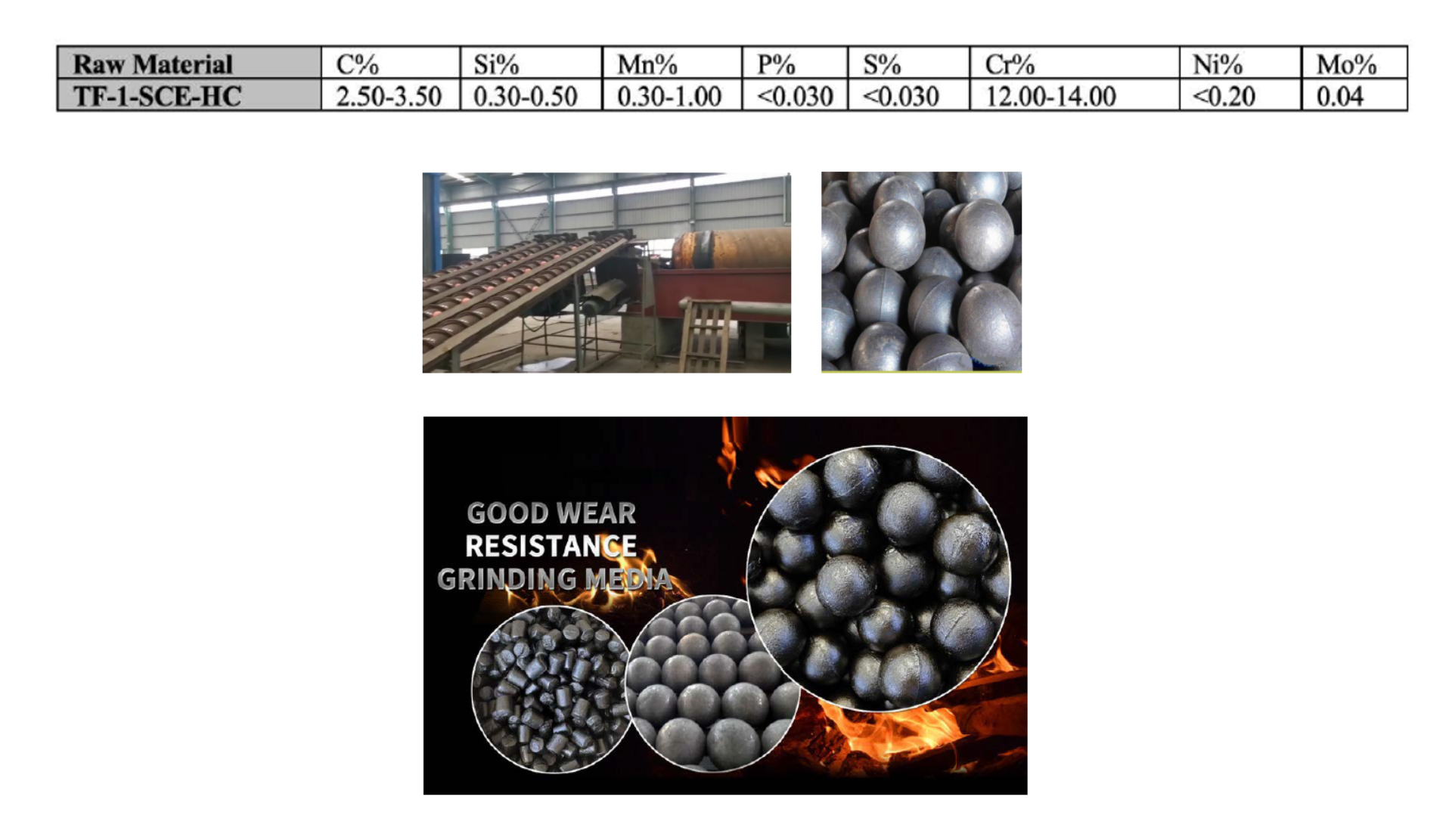

- Casted High Chrome Balls Chemical Composition

- Jaw & Cone Crusher Liners

As SCE aims to provide spare parts for crushing equipments; We provide our

customers high quality Jaw liners (fixed & movable) with 18-22 % of Mn.

Furthermore, bowl & mantle liners for cones we offer wide range of same for most

well known world wide crushers suppliers with high quality and reliability products.

If you need such products don’t hesitate and call us now to supply your plant spares.

- Hard Steel & Fabrications

As SCE mission to be a One – Stop – Workshop we expand our scope of work adding cutting,

bending and drilling machines to our state of art machine shop to meet our clients requirements

in mining and contracting industries.

In addition, we are now a dealer of Dillinger – Germany hard steel products which manufactured

a Dillidur hard steel brand. Offer wide range of solutions in fabrications parallel with casting and

forging departments.

Our customers will be offered liners, hard steel plates, buckets re-conditioning and chutes

fabrications with hard steel gardes starting from 400 BHN to 600 BHN.

The added value over this is Chromium Carbide Overlay plates (CCO) plates with pure sliding

wear rate which gives 2X life than 600BHN hard steel.